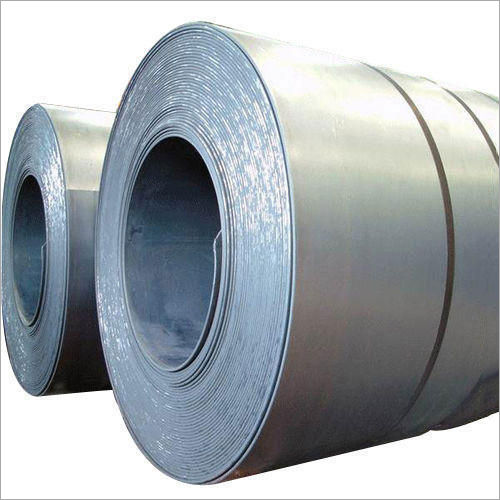

Hrco Coils

69000 INR/Metric Ton

Product Details:

- Surface Treatment Galvanized

- Material Mild Steel

- Technique Hot Rolled

- Grade HR/CR

- Coil Thickness 0.3 mm - 3.0 mm

- Coil Weight Standard

- Coil Length Custom Length

- Click to View more

X

Hrco Coils Price And Quantity

- 69000 INR/Metric Ton

- 3 metric tone Metric Ton

Hrco Coils Product Specifications

- Standard

- HR/CR

- Mild Steel

- Galvanized

- 0.3 mm - 3.0 mm

- Custom Length

- Industrial, Construction, Fabrication, Automobile

- Hot Rolled

- High Strength

Hrco Coils Trade Information

- Mumbai

- Cheque

- 100000 Metric Ton Per Day

- 3-4 Days

- Contact us for information regarding our sample policy

- As per requirements

- Middle East

- All India

- ISO

Product Description

HRCO Coils are suited for the medical equipment and industrial manufacturing. They convey electricity to commercial and residential buildings. These have been made to run into the individual specific needs of assorted processes. They are apt for the manufacturing of general fabrications, steel sheets, commercial tubes, and corrugated steel. HRCO Coils are suited for the sector of oil and gas pipelines. They are also applicable for gas cylinders as well as pressure vessel tanks. They are perfect for making pipes which are suited for the construction of tanks, bicycle frames, railway cars, ships, military equipment, and engineering equipment.

Versatile Coil Dimensions and Edges

Hrco Coils are available in various widths, from 600 mm up to 2000 mm, and allow selection of either mill edge or slit edge for greater adaptability in different industrial processes. This flexibility ensures that your project requirements for sizing and edge finishing are always met.

Reliable Galvanized Surface and Metallic Grey Appearance

With superior galvanized surface treatment, Hrco Coils offer increased protection from corrosion and wear, maintaining their metallic grey finish. This not only enhances the coil's durability but also provides a clean, professional look for visible applications.

Custom Packaging and Export-Ready Solutions

Every Hrco Coil is securely packed using standard export packaging methods to ensure safe delivery and handling. Our solutions are suitable for both domestic use and international export, offering hassle-free sourcing for suppliers, traders, and service providers in India.

FAQ's of Hrco Coils:

Q: How can Hrco Coils be customized in terms of size and length?

A: Hrco Coils are highly customizable, with available widths from 600 mm to 2000 mm and coil thickness options between 0.3 mm and 3.0 mm. The coil length can be tailored to meet your specific project requirements, meaning you receive precisely what you need for fabrication, construction, or industrial usage.Q: What surface treatments are applied to Hrco Coils and what benefits do they offer?

A: The coils are treated with a galvanized finish that provides robust protection against rust, corrosion, and environmental exposure. This enhances the longevity and reliability of the coils, making them well-suited for demanding environments and extended use.Q: When is it recommended to choose mill edge or slit edge for Hrco Coils?

A: Selecting a mill edge or slit edge depends on your application and desired finish. Mill edge is typically suitable for processes that will further trim or shape the coil, while slit edge is preferred for ready-to-use strips with smoother edges and more precise width control.Q: Where are Hrco Coils commonly used?

A: Hrco Coils are widely employed across industries including industrial machinery production, construction frameworks, fabrication workshops, and automobile manufacturing. Their high strength and customizable properties make them a preferred choice for both structural and component applications.Q: What is the process involved in manufacturing Hrco Coils?

A: Hrco Coils are produced using the hot rolled steel technique, which involves heating mild steel beyond its recrystallization temperature and rolling it into thin sheets or coils. This process delivers high strength and optimal mechanical properties for various industry standards such as ASTM, JIS, and DIN.Q: How does standard export packing benefit customers of Hrco Coils?

A: Standard export packing safeguards the coils during transportation, ensuring they arrive without damage or deformation. This reliability is essential for both local and international customers, assuring them of consistent quality upon receipt.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email